why creep occurs at high temperatures|3 stages of creep failure : service Creep is the time-dependent plastic deformation of a metal or mate - rial under load. Creep usually occurs at high temperatures but can also occur at room temperature. Good .

WEB17 de dez. de 2022 · UOL. A Caixa Econômica Federal realizou neste sábado (17) o concurso 6027 da Quina, mas de acordo com o banco não houve vencedores na edição. O prêmio que era de pouco mais de R$ 8,8 .

{plog:ftitle_list}

WEBDownload Thunderstruck-2012-DVDRip-Castellano.torrent fast and free from Hostr - Get free file hosting, and cloud sharing with Hostr. 30 Mar 13 at 6:32 PM 80.7KB 3,948 downloads

Creep behavior can be split into three main stages. In primary, or transient, creep, the strain rate is a function of time. In Class M materials, which include most pure materials, primary strain rate decreases over time. This can be due to increasing dislocation density, or it can be due to evolving grain size. In class A materials, which have large amounts of solid so.Outline. • Creep and high temperature failure • Creep testing • Factors affecting creep • Stress rupture life time behaviour • Creep mechanisms • Example • Materials for high creep . Creeps are characterized as time-dependent permanent deformations that occur under constant stress at elevated temperatures. The material composition determines the onset of creep. For example, steel .

Creep also occurs at high temperatures when non-evaporable water is removed and this is thought to be due to movement of interlayer or zeolitic water, viscous flow or sliding .time of materials at high temperatures. Creep is a performance-based behaviour since it is not an intrinsic materials response. Furthermore, creepis highly dependent on environment .Creep is the time-dependent plastic deformation of a metal or mate - rial under load. Creep usually occurs at high temperatures but can also occur at room temperature. Good . Creep of crystalline materials at high temperatures is a thermally activated process and is governed by the mobility of point or line defects. Shear or sliding in the grain .

The rate of creep of a material is strongly dependent on stress and temperature. Besides stress and temperature, the creep rate also depends on the grain size at a temperature above 0.5 of . Creep mechanics focuses on modeling the mechanical behavior of engineering components made of metals or alloys at elevated temperatures (0.3–0.7 of the melting .However, in polymers, creep occurs through a different process: the localised rotation and stretching of their polymer chains. Temperature and Creep: While temperature is a crucial factor affecting creep in both metals and polymers, the degree to which it does varies. Polymers, for instance, begin to exhibit significant creep behaviour at . The ATI 718Plus ® is a creep-resistant nickel-based superalloy exhibiting high strength and excellent oxidation resistance in high temperatures. The present study is focused on multiscale 2D and 3D characterization .

Creep is a major concern, since it can cause materials to progressively deform, and possibly to fail, under applied stresses below their yield stress. . Have an appreciation of the mechanisms involved in creep deformation, and their general dependence on temperature and stress; Understand what is meant by Primary, Secondary and Tertiary Creep . In Nabarro-Herring creep, which occurs at higher temperatures, diffusion happens through grain interiors, while Coble creep occurs at relatively lower temperatures through grain boundaries. . The damage mechanism in the high-temperature creep tests of ferrite was similar to that reported by Hervas et al. .

Having a high melting point of 2798 °C, it is expected that creep may occur at high homologous temperatures. In Fig. 6.25, a set of creep curves are shown, pre-strained by tension at various rates at 1800 °C to induce dislocation structures. Creep tests were performed at 1400 °C and under a stress of σ = 44.1 MN/m 2. The focus here is on . During high-temperature creep, Re is easily expelled from the γ′ phase under high temperatures and applied loads, increasing the diffusion ability of other elements and resulting in KW being activated again to slip on the {111} plane, which is the main reason why the alloy containing only Re retains less of a KW lock under high-temperature . A constitutive model for the high-temperature creep of particle-hardened alloys based on the θ projection method. Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences. 2000; 456 (1996):835-868; 18. Dyson BE, McLean M. Microstructural evolution and its effects on the creep performance of high temperature .

Study with Quizlet and memorise flashcards containing terms like Define the process of creep, Describe logarithmic or low temperature creep, Describe the change in creep behaviour under high temperatures, explaining the significance of high temperature and describing 3 reasons why the change occurs. and others. temperatures depending upon the type used. It is important to recognize that for high-temperature service, strength at temperature is related to time at temperature. Allowable Deformation Another factor to consider in designing for high-temperature service is the amount of deformation that can be permitted during the total service life.Understanding Creep Deformation. Creep deformation refers to the gradual and time-dependent deformation of materials under constant stress. This is particularly relevant for materials exposed to high temperatures, although it can also occur at ambient temperatures.

Many crystalline materials are known to exhibit creep at low temperatures (T < 0.3T m). Here, we review and analyze the phenomenological relationships that describe primary creep. The discussion focuses on the controversy as to whether power-law or logarithmic descriptions better describe the experimental database. We compile data from the literature as well as new .

Creep in metals at high temperatures refers to time-dependent inelastic deformations that occur when temperature of the material exceeds 0.3–0.4 times of its absolute melting temperature [2, 3]. As the surface temperature of the slab is higher than 900 °C, the slab shows strong creep characteristics in present steel continuous casting . Creep testing reveals how high-temperature materials deform over time under constant stress, critical for designing durable components. . Thus, a greater grain-boundary area allows easier creep deformation. Creep failure occurs when there is no significant deformation of the grains along the boundary. Creep strength can thus be improved by .

TALAT 1253 6 Equations 2 and 3 can be combined, giving: A n ()Q RT ε&SS = σ exp − / (4) where A is a material parameter. While in pure metals n does not depend on temperature, and Q does not depend on stress, in many engineering alloys a complex dependence of Q on applied stress, and a high or very high (7-20) value of the temperature-dependent stress exponent n .

Creep is the time-dependent, permanent deformation of a material at elevated temperatures. Understanding creep behavior provides insights for design improvements and quality assurance. It can really wreak havoc for . The creep test measures the dimensional changes that occur at elevated temperature exposure, while the stress rupture test measures the effect of temperature on long-time, load-bearing properties. Creep testing is a .What is Creep Deformation. Creep deformation is a type of plastic deformation that occurs when materials are subjected to continual stress over a long period of time. This phenomenon can happen if high loads are applied for extended .

special tests for labral tear

alloy, however, creep can be demonstrated at room temperature, and the creep of common lead + tin solder is the subject of this experiment. Lead-tin solder has a melting point of 183 C (456 K), so room temperature at 298K is more than half the melting temperature. Thus we would expect creep to occur at room temperature in solder if it is put .The use of metals at high temperatures introduces the possibility of failure in service by a mechanism known as creep. . The third stage, tertiary creep, occurs when the creep life is almost exhausted, voids have formed in the material and the effective cross sectional area has been reduced. The creep rate accelerates as the stress per unit .The reduction in the creep rate that occurs near the end of the primary creep stage is due to work hardening. Stage 2: Secondary Creep. Secondary creep begins once the strain rate begins to stabilize and becomes constant. The strain during secondary creep occurs relatively slowly when compared to the first stage and the third stage of creep.

Creep also occurs at ambient temperatures; for example, creep occurs in pre-stressed concrete beams, which are held in compression by steel rods. . Creep testing involves the application of a constant load to a specimen at a high temperature (see Fig. 14.4). A creep test is used to determine the amount of defor-The physics of high temperature creep in metals. D McLean 1. Published under licence by IOP Publishing Ltd Reports on Progress in Physics, Volume 29, Number 1 Citation D McLean 1966 Rep. Prog. Phys. 29 1 DOI 10.1088/0034-4885/29/1/301. Download Article PDF. Figures. Skip to each figure in the article. The dependences of creep strain and creep strain rate on testing time are illustrated in Fig. 1.As can be seen in Fig. 1 (a), the creep strain increased exponentially with testing time until the specimen was ruptured (at a strain of~30%). The creep strain rate in Fig. 1 (b) shows a typical three-stage creep features: the primary creep with a fast increment from 3 .High-temperature creep occurs well in Fe–17Cr–1.2Cu–0.5Nb–0.01C ferritic heat-resistant stainless steel due to the dominant generation of Cu-rich phase and Nb-rich Laves particles during the creep process. The interaction between these precipitates and dislocations controls the diffusion-controlled dislocation creep mechanism, leading .

It can be seen that Eq. (6) can really represent complicate creep curves of high temperature alloys very accurately. Download: Download high-res image (1MB) Download: Download full-size image; Fig. 3. (color online) Comparisons of creep constitutive relationship with experimental results for GH4169: (a) at 550°C, (b) at 600°C, (c) at 650°C.Low Temperature: High Temperature: Metals: Low creep rate: High creep rate: Ceramics: Creep resistance: Creep occurs under high stress: Polymers: Creep noticeable: Creep accelerates: All these facts underline the diversity of materials' responses to the stages of creep. It's through detailed understanding and examination of these extensive . Creep of crystalline materials at high temperatures is a thermally activated process and is governed by the mobility of point or line defects. . test (SRRT) to a commercially forged titanium-base alloy in evaluating: irreversible viscous strain, during primary creep at a constant temperature and quasi-constant microstructure, and its use to .

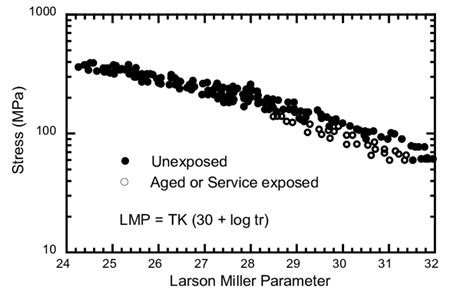

stress vs larson miller parameter

phenomenon of creep

23 de mar. de 2020 · "Desconfio que minha filha de 15 anos esteja transando com o namorado. Devo falar com ela, ou seria uma invasão de privacidade? Como ter certeza .

why creep occurs at high temperatures|3 stages of creep failure